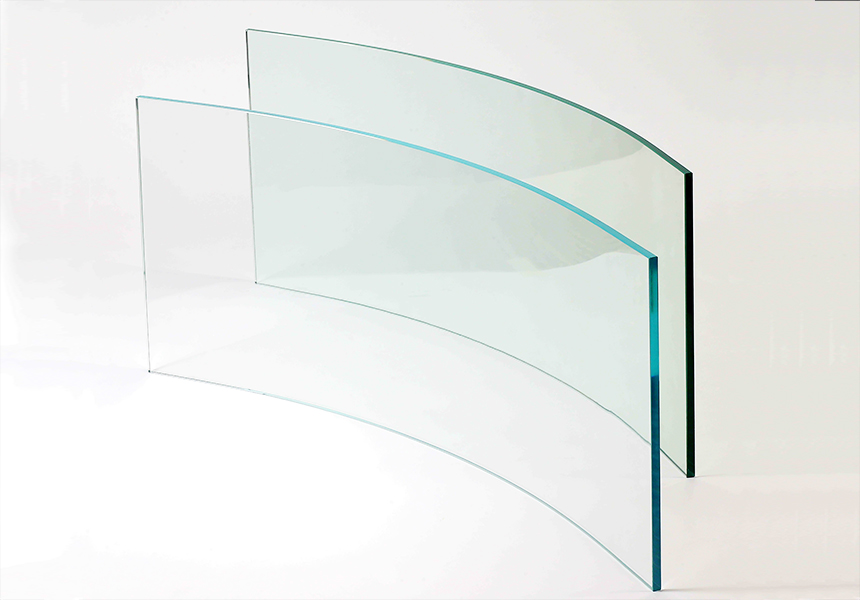

The integrated gear system controlling the process allows for

millimetre precision, enabling us to fulfil even the most demanding requirements.

We process the curved glass through our top-and-bottom convection heating

system, offering panels in tempered, heat-strengthened, and heat-soaked variants.

We can laminate and insulate these panels to fulfil all your façade needs with ease.

Each pane is bar-code labelled and scanned at the entry and exit points of the furnace, thus recording the exact time of the production process. The timestamp helps in determining process parameters for backward traceability, ensuring complete quality assurance.

Custom-developed production software helps in confirming all previous fabrication stages are completed correctly before the final tempering process is initiated through bar-code tracking and reporting, ensuring the right product is manufactured.

The furnace is equipped with energy metres that constantly monitor energy consumption.

| Feature | Description |

| Process Type | Horizontal Roller-Heart Convection Furnace |

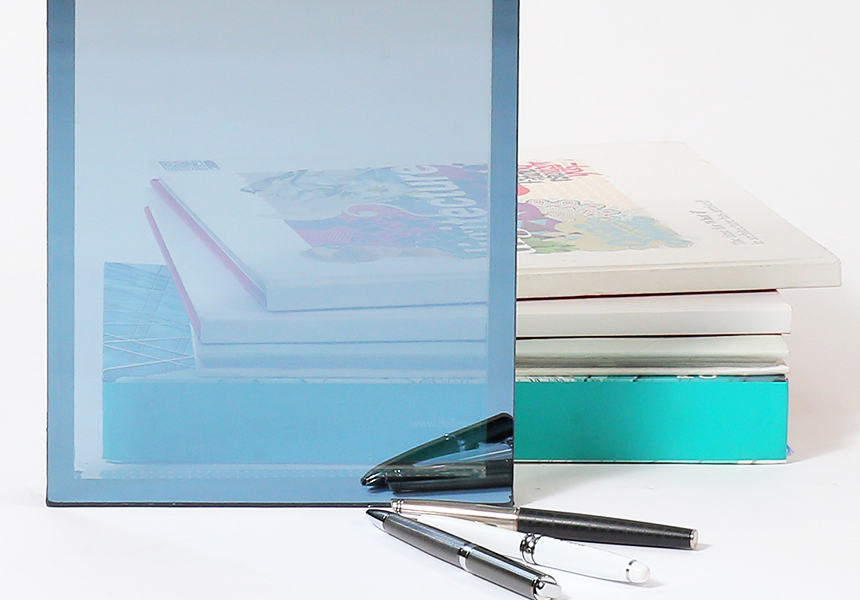

| Glass Types | Clear, extra clear, ultra clear, tinted, solar-control coated, low-E coated |

| Additional Process Compatibility | Ceramic frit, DIGIVIEW digital printing, sand-blasting, acid etching, holes, cutouts, and notches |

| Product Enhancement | Can be converted to ecoTHERM™ (insulated glass), ecoLAM™ (laminated glass), BULLETSHIELD™, or BURGLARSHIELD™ |

| Glass Thickness | 5 mm to 19 mm |

| Edge Types | Rough grind, arrissed, super polished |

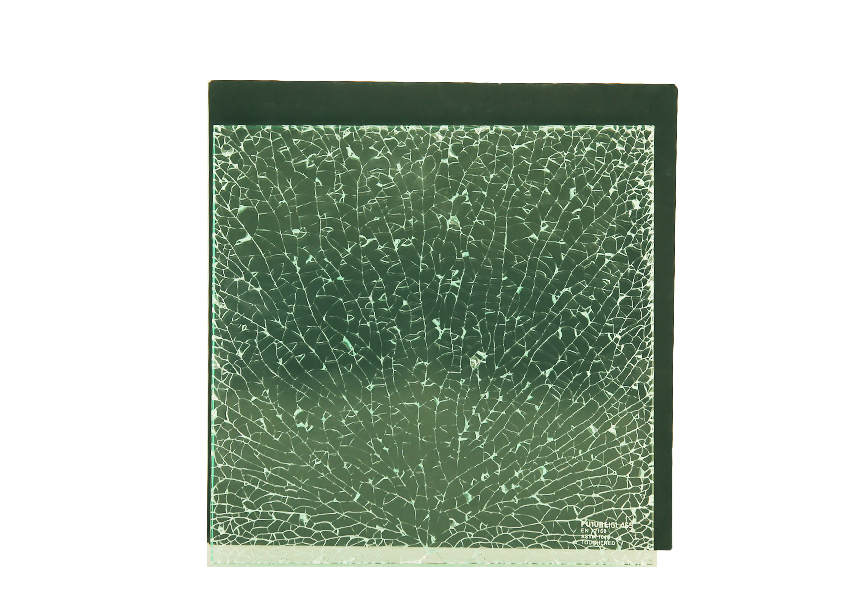

| Compressive Stress (Surface) | 30 MPa to 52 MPa or 4,300 psi to 7,500 psi – Heat-Strengthened 69 MPa or 10,000 psi minimum – Fully Toughened |

| Emissivity | Minimum 0.01** |

The gear-operated cylindrical bending machine offers better control and precision. Our state-of-the-art top-and-bottom forced turbo-charged convection system allows heat-strengthening and soaking. We use a heat scanner with precise measurement points to check the quality of each panel.

Our Litesentry equipment enables us to ensure 100% real-time tracking of each glass panel. Additionally, it allows us to ensure quality control and minimal optical distortion.

ecoLAM™ is a laminated glass unit with interlayers joining two or more glass lites together. We source our interlayers only from Kuraray™ and Eastman™, ensuring the highest possible quality.

ecoTHERM™ Insulated Glass Units (IGUs) have two or more glass lites separated by a desiccated air space, offering better thermal efficiency.

Our ecoSHIELD™ fully tempered glass is up to five times stronger than annealed glass of the same thickness.

Give us a call or send us an email and we will get back to you as soon as possible!

Contact Us

Future Architectural Glass, LLC (Future Glass) is a joint venture between a multinational & diversified Singapore corporation and a leading Indian glass conglomerate. The company has positioned itself to establish itself as UAE's premium glass processor having the entire gamut of European machinery and systems to process any type of interior and exterior glass.

Since 1976, the group has been serving the needs of the architectural glass market by providing the latest products suiting the dynamic needs of architects/consultants. We started operations as a glass trading and distribution firm and ever since have expanded our products and services to include safety glass manufacturing and providing specialty glass solutions.