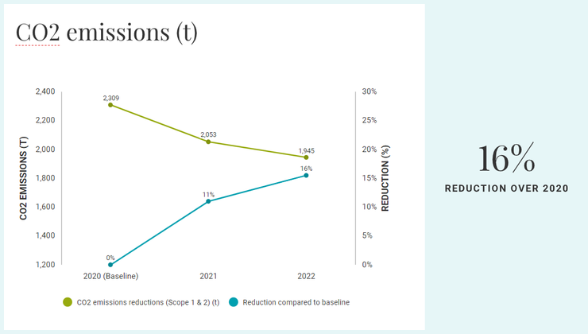

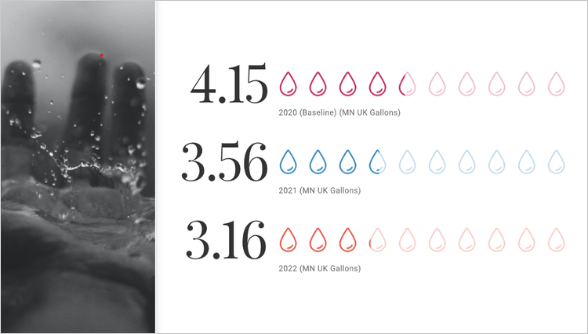

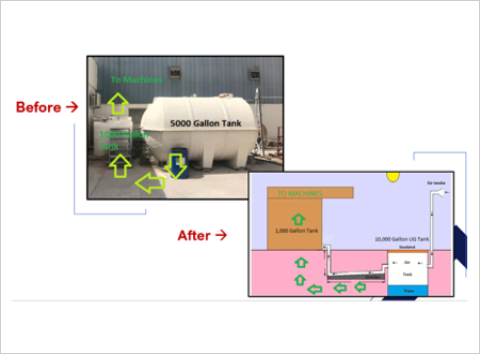

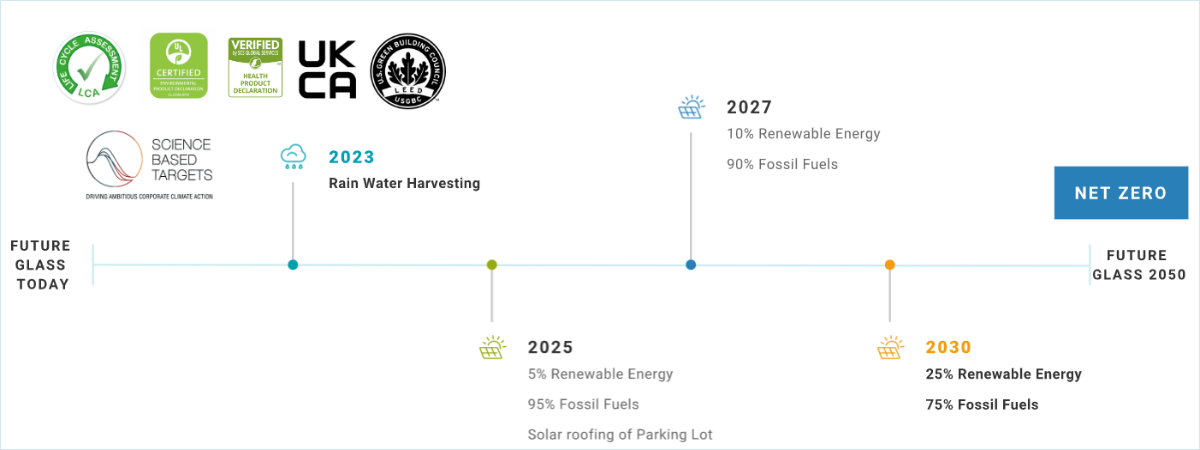

Our Present - Reducing our Carbon Footprint

We embarked on our sustainability journey at the peak of the COVID-19 lockdowns and restrictions. From the pandemic, we learned there is opportunity in adversity. We shifted our focus to become more resilient and committed towards sustainability. Despite the humble beginning, we took the first step in the right direction.