These multi-layer panels get laminated with polycarbonates to minimise the risk of flying glass debris after an explosion. It’s important to note that blast-resistant windows do not function in isolation – they only work as part of a system involving the glass, framing and anchoring system, and the structure of the building. If the framing or anchoring system is not blast-resistant, it may be unable to hold the glazing in the event of a blast, which may cause the glass panel to fail. We will provide you with a qualified blast engineer who will help you create the ideal design for your blast-resistant project.

We use computer-assisted calculations to determine the thickness of layers required to contain the blast and correlate the test results to the project requirements.

Panels can be custom designed or coated with any RAL colour for enhanced aesthetics. We can incorporate low-iron ultra clear glass for heightened visibility or process curved panels to meet complex design requirements.

ISO 16933 Classification Criteria

| Classification | Peak Pressure of the Shock Wave (kPa) | Positive Impulse (kPA-ms) |

| EXV45(X) | 30 | 180 |

| EXV33(X) | 50 | 250 |

| EXV25(X) | 80 | 380 |

| EXV19(X) | 140 | 600 |

| EXV15(X) | 250 | 850 |

| EXV12(X) | 450 | 1200 |

| EXV10(X) | 800 | 1600 |

| Performance Condition. | Security Level. | Hazard Level. | Description of Window Glazing Response |

| 1 | Safe | No breakage | Glazing does not break No visible damage to glazing or frame |

| 2 | Very High | No risk | Glazing cracks but is retained by the frame Dusting or very small fragments near sill or on floor acceptable |

| 3A | High | Minimal risk | Glazing cracks and fragments enter space and land on the floor, no further than 3.3 feet from the window |

| 3B | High | Very low risk | Glazing cracks and fragments enter space and land on the floor, no further than 10 feet from the window |

| 4 | Medium | Low risk | Glazing cracks and fragments enter space and land on the floor and impact a vertical witness panel at a distance of no more than 10 feet from the window and at a height no greater than 2 feet above the floor |

| 5 | Low | High risk | Glazing cracks and window system fails catastrophically Fragments enter space, impacting a vertical witness panel at a distance of no more than 10 feet from the window and at a height no greater than 2 feet above the floor |

We process and test our BLASTSHIELD panels for use in curtain walls, doors and windows to protect from inside and outside threats.

All our panels get tested according to ISO 16933 and US-GSA standards.

We use computer-assisted calculations to determine the thickness of layers required to contain the blast and correlate the test results to the project requirements.

Our in-house blast engineer will provide a consultation to understand your safety requirements and suggest the glass and glazing required to meet them. Once we process the glass and glazing system, we will install it on-site to ensure it meets the required safety standard.

We can build and engineer attractive blast-resistant glass and glazing systems in various colours to meet the design requirements.

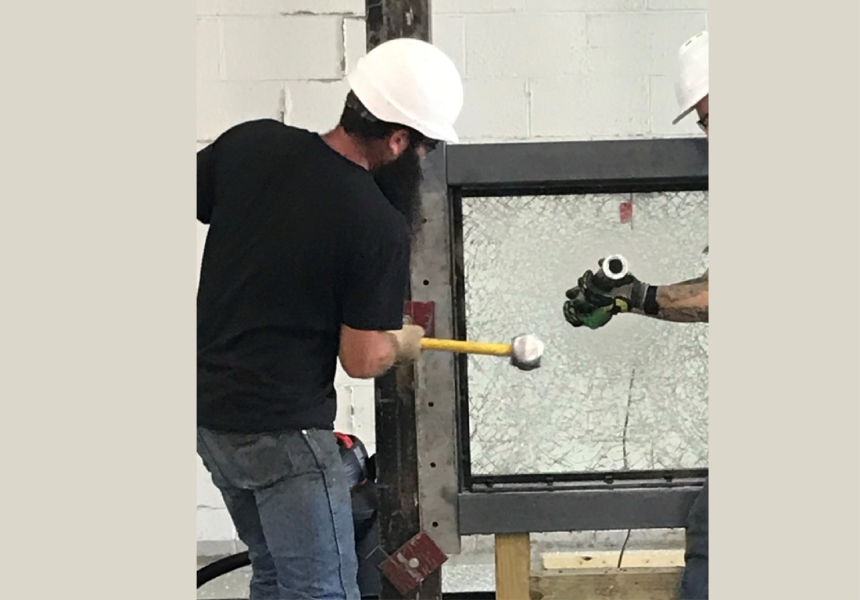

BURGLARSHIELD™ is our range of impact-resistant panels that can withstand forced penetration attacks from mallets, saws, and bars.

BULLETSHIELD™ is an industry-leading glass designed to uphold even the most demanding bullet impact protection requirements.

ecoLAM™ is a laminated glass unit with interlayers joining two or more glass lites together. We source our interlayers only from Kuraray™ and Eastman™, ensuring the highest possible quality.

Give us a call or send us an email and we will get back to you as soon as possible!

Contact Us

Future Architectural Glass, LLC (Future Glass) is a joint venture between a multinational & diversified Singapore corporation and a leading Indian glass conglomerate. The company has positioned itself to establish itself as UAE's premium glass processor having the entire gamut of European machinery and systems to process any type of interior and exterior glass.

Since 1976, the group has been serving the needs of the architectural glass market by providing the latest products suiting the dynamic needs of architects/consultants. We started operations as a glass trading and distribution firm and ever since have expanded our products and services to include safety glass manufacturing and providing specialty glass solutions.