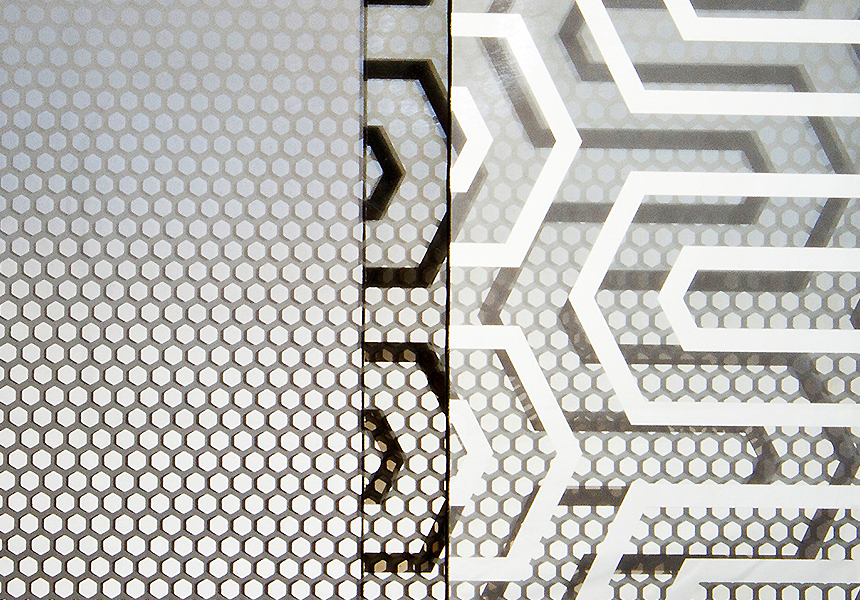

You can pick a colour and pattern of your choice to create a stylish façade that enhances privacy. You can select a design to get printed on clear, tinted or coated glasses. Once we transfer the ink onto the glass surface, we fire it in the furnace at 650°C to reduce scratching and peeling. You can customise the panel to make it fully tempered or heat-strengthened to boost your façade’s security.

We can offer crisp and sharp outlines, ensuring complete alignment for dual-sided frits with colours of your choice on one side and black on the other. The neutral inner treatment makes the frit almost imperceivable when viewed from inside, giving you the desired aesthetics with neutral interiors.

Each pane is bar-code labelled and scanned at the entry and exit points of the furnace, thus recording the exact time of the production process. The timestamp helps in determining process parameters for backward traceability, ensuring complete quality assurance.

Custom-developed production software helps in confirming that all previous fabrication stages are completed correctly before the final tempering process is initiated through bar-code tracking and reporting, ensuring the right product is manufactured.

| Feature | Description |

| Process Type | Screen printed or spray painted |

| Glass Types | Clear, extra clear, ultra clear, tinted, solar-control coated, low-E coated |

| Additional Process Compatibility | Sand-blasting, acid etching, holes, cutouts and notches |

| Product Enhancement | Can be converted to ecoTHERM™ (insulated glass), ecoLAM™ (laminated glass), or to our fire safety, security and creations glass ranges |

| Glass Thickness | 4 mm to 25 mm |

| Edge Types | Rough grind, arrissed, super polished |

| Compressive Stress (Surface) | 30 MPa to 52 MPa or 4,300 psi to 7,500 psi – Heat-Strengthened 69 MPa or 10,500 psi minimum – Fully Toughened |

| Ink Makes | Torrecid (Spain), Ferro (Germany), or Fenzi (Italy) |

We source our inks from quality suppliers in Europe. They and eco-friendly, have zero lead content and prevent flaking and peelings.

We use a heat scanner with precise measurement points to ensure the perfect quality of each panel every time.

Our Litesentry equipment enables us to ensure 100% real-time tracking of each glass panel. Additionally, it allows us to ensure quality control and minimise optical distortion.

Enjoy vibrant aesthetics with our range of back-painted panels, COLORVIEW. We can use multiple colours and techniques with gradients and special effects to meet design requirements.

Our CHROMVIEW® panels combine the durability, safety, and corrosion resistance of glass with the reflective properties of mirrors.

DIGIVIEW enables architects and interior designers to create unique spaces with high-resolution digital printed glass.

Give us a call or send us an email and we will get back to you as soon as possible!

Contact Us

Future Architectural Glass, LLC (Future Glass) is a joint venture between a multinational & diversified Singapore corporation and a leading Indian glass conglomerate. The company has positioned itself to establish itself as UAE's premium glass processor having the entire gamut of European machinery and systems to process any type of interior and exterior glass.

Since 1976, the group has been serving the needs of the architectural glass market by providing the latest products suiting the dynamic needs of architects/consultants. We started operations as a glass trading and distribution firm and ever since have expanded our products and services to include safety glass manufacturing and providing specialty glass solutions.