Having serviced London’s real estate market for over a quarter of a century, Galliard Homes is the English capital’s largest privately owned residential developer. Over their years in the business, Galliard has become synonymous with regeneration, rejuvenation and reinvention.

Providing a wide range of façade design and engineering services to real estate companies across Europe, Yuanda has been transforming the continent’s skylines for over a decade. By offering a combination of European system design and Chinese materials and fabrication, Yuanda continues to provide world-class and cost-effective façade solutions to the UK, France, Germany and Switzerland.

The Harbour Central project was conceptualised to transform the London Docklands into an up-and-coming residential area. The project, which comprises 5 residential towers, boasts a total façade area of 63,000 square metres. The façades were designed to superimpose a metal mesh on the shadow box area and showcase the aesthetics of the blocks. Moreover, the team of architects at Rolfe Judd had very precise specialty glazing requirements for the buildings.

The Harbour Central project brought together a team of world-class architects from Rolfe Judd, façade specialists from Meinhardt and Yuanda Europe and real estate experts from Galliard Homes. As a direct result of this, decisions regarding the façade and design were made keeping the most exacting international standards in mind.

The key challenges were to:

The search for the perfect glass led us across countries and continents. After an exhaustive search, the silver mesh was procured from Germany while the gold mesh was procured from Italy. Since the glass panels required were of a very large size, an innovative solution was sought by which panels of a maximum size of 1,500 mm x 4,000 mm were created with the metal mesh suspended in the cavity of the IGU. To put concerns about mesh sagging and distortion to rest, a sample panel was provided to the client.

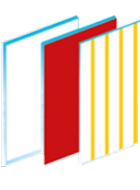

For energy efficiency, Climaguard Premium 2T, a high performance Low-E coated glass was procured from Guardian Glass in Europe. The glass itself is made up of a combination of products. The outer-lite is a clear ecoLAM (HS) of 10.76 mm. The expanded metal mesh infill is within a 24 mm black spacer with argon gas. Finally,

the inner lite is a 6 mm clear ecoFACADE (HS). Despite the complicated product combination, the performance specifications were designed to meet the client’s requirements perfectly. A total of about 4,100 square metres of finished insulated glass units with expanded metal mesh were provided for the Harbour Central project.

At Future Glass’ state-of-the-art facility in UAE, a dedicated workforce was tasked with ensuring the high-specialty glass was treated in a sterile environment where temperature and humidity could be controlled. Each glass panel is handmade and pieced together under the supervision of qualified engineers.

The finished glass panels were placed in IPPC-certified wooden crates for transport. As per local requirements, each piece was individually banded and then shipped to Yuanda’s Shenyani factory. From there, the panels were carefully assembled into a framing system that was delivered to the site in London. Despite the fact that the materials were sourced from various countries, the logistics and operations team took every precaution necessary to ensure zero breakages during the delivery process. In case panels needed to be replaced, we did what was necessary without impacting the timelines, even though it was difficult to procure smaller quantities of mesh from the supplier.

Give us a call or send us an email and we will get back to you as soon as possible!

Contact Us

Future Architectural Glass, LLC (Future Glass) is a joint venture between a multinational & diversified Singapore corporation and a leading Indian glass conglomerate. The company has positioned itself to establish itself as UAE's premium glass processor having the entire gamut of European machinery and systems to process any type of interior and exterior glass.

Since 1976, the group has been serving the needs of the architectural glass market by providing the latest products suiting the dynamic needs of architects/consultants. We started operations as a glass trading and distribution firm and ever since have expanded our products and services to include safety glass manufacturing and providing specialty glass solutions.