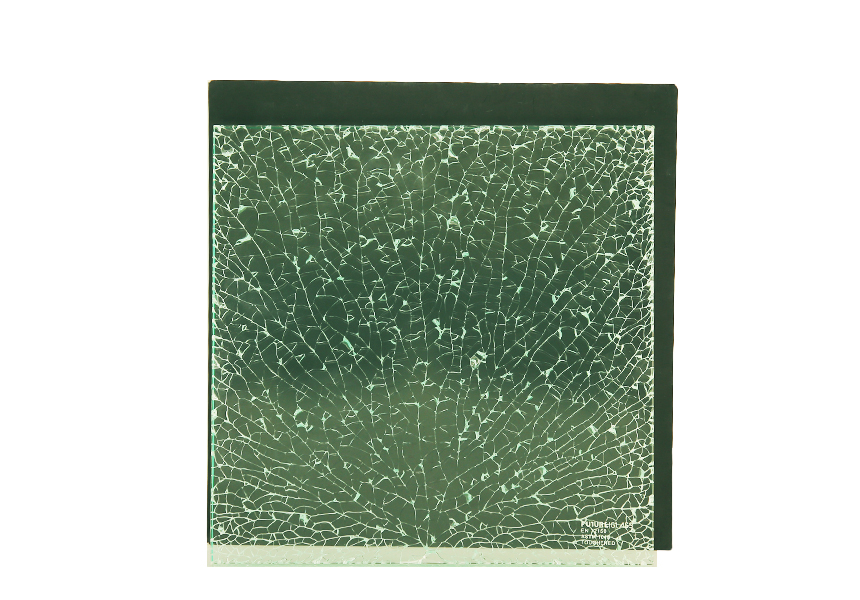

We use our state-of-the-art horizontal roller hearth convection furnace, with top and bottom heating, to process these panels, following which our advanced and precise cooling system ensures very high glass flatness. Our processes minimise the risk of spontaneous breakage due to the presence of nickel sulphides, making ecoSHIELD™ an ideal fit for your façade requirements.

Each pane is bar-code labelled and scanned at the entry and exit points of the furnace, thus recording the exact time of the production process. The timestamp helps in determining process parameters for backward traceability, ensuring complete quality assurance.

Custom-developed production software helps in confirming all previous fabrication stages are completed correctly before the final tempering process is initiated through bar-code tracking and reporting, ensuring the right product is manufactured.

Furnace is equipped with energy meters that constantly monitor the energy consumption. Utilising Industry 4.0 techniques with the help of intuitive software, the system suggests better furnace loading patterns/bed utilisation to produce the panes with lower energy levels.

| Feature | Description |

| Process Type | Horizontal Roller-Hearth Convection Furnace |

| Glass Types | Clear, extra clear, ultra clear, tinted, solar-control coated, low-E coated |

| Additional Process Compatibility | Ceramic frit, DIGIVIEW digital printing, sand-blasting, acid etching, holes, cutouts and notches |

| Product Enhancement | Can be converted to ecoTHERM™ (insulated glass) and ecoLAM™ (laminated glass) |

| Glass Thickness | 4 mm to 25 mm |

| Edge Types | Rough grind, arrissed, super polished |

| Compressive Stress (Edge) | 67 MPa or 9,700 psi minimum |

| Compressive Stress (Surface) | 69 MPa or 10,000 psi minimum |

| Emissivity | Minimum 0.01** |

Our ecoSHIELD™ panels can be customised with advanced coatings and laminated or insulated depending on your façade needs.

We use our state-of-the-art top-and-bottom forced turbo-charged convection system, heat-scanner with precise measurement points and dual-oscillating quenching technology to ensure that each ecoSHIELD™ panel surpasses the most stringent quality checks.

Our Litesentry equipment enables us to ensure 100% real-time tracking of each glass panel. Additionally, it allows us to ensure quality control and minimise optical distortion.

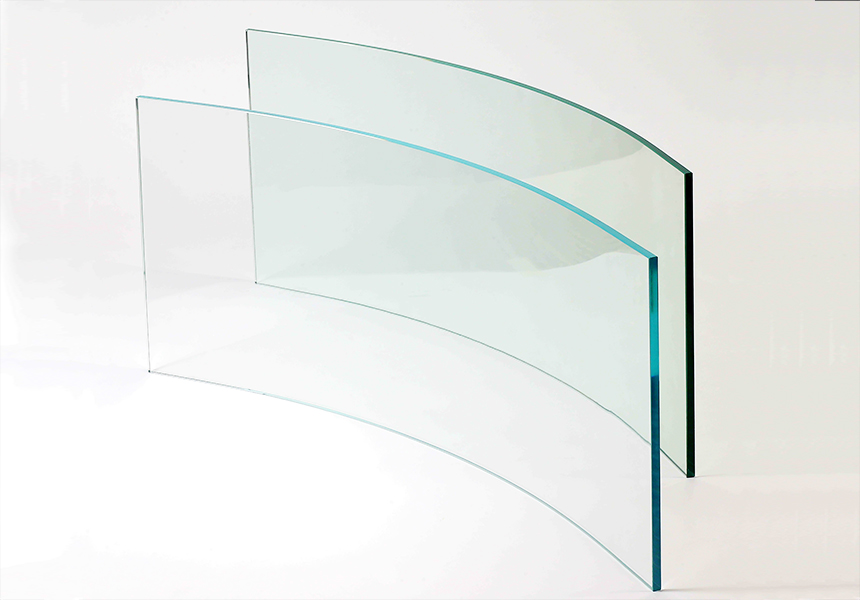

Fulfil all your unique façade needs with CURVEVIEW™. We process the curved glass on our state-of-the-art cylindrical bending system that ensures an even radius through the width of the glass.

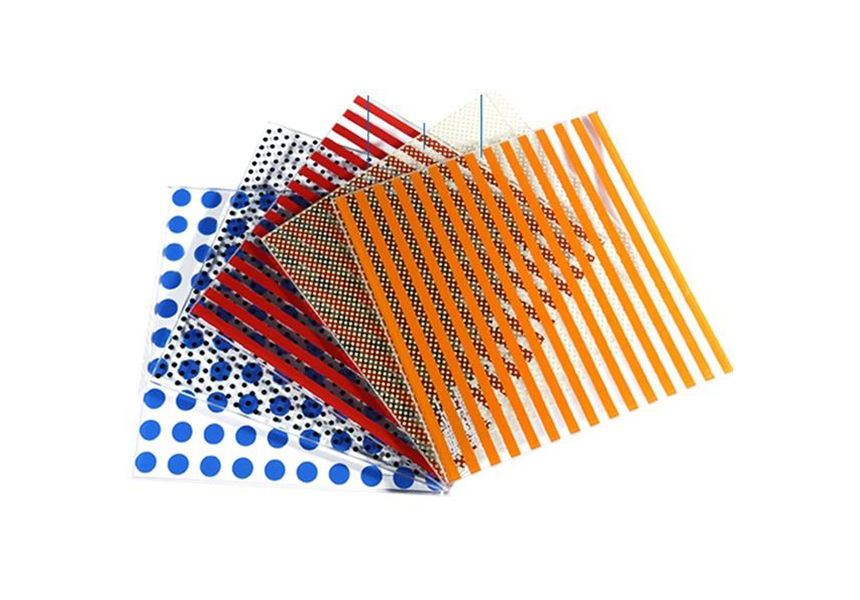

Upgrade your building’s façade with our ceramic fritted glass, FRITVIEW™. These panels are processed through a silk screen or spray painted to fuse ceramic inks on the glass.

CLAROVIEW is a specialised glass product that reduces the surface reflection. The panels maximise visibility while minimising reflection.

Give us a call or send us an email and we will get back to you as soon as possible!

Contact Us

Future Architectural Glass, LLC (Future Glass) is a joint venture between a multinational & diversified Singapore corporation and a leading Indian glass conglomerate. The company has positioned itself to establish itself as UAE's premium glass processor having the entire gamut of European machinery and systems to process any type of interior and exterior glass.

Since 1976, the group has been serving the needs of the architectural glass market by providing the latest products suiting the dynamic needs of architects/consultants. We started operations as a glass trading and distribution firm and ever since have expanded our products and services to include safety glass manufacturing and providing specialty glass solutions.