Superior Infrastructure, Superior Quality, because you deserve the best!

Cutting Robot @ Work

Speed & consistency

A highly advanced fully automated Hegla (Germany) warehousing & Cutting system controlled by networked software systems offering one-touch control over job orders. Turning architect’s dreams to reality by offering capability to handle stock sheets size up to 7200 x 3300mm.

A reliable system equipped with twin edge deletion features & twin cutting heads to facilitate today’s challenging requirements with ease.

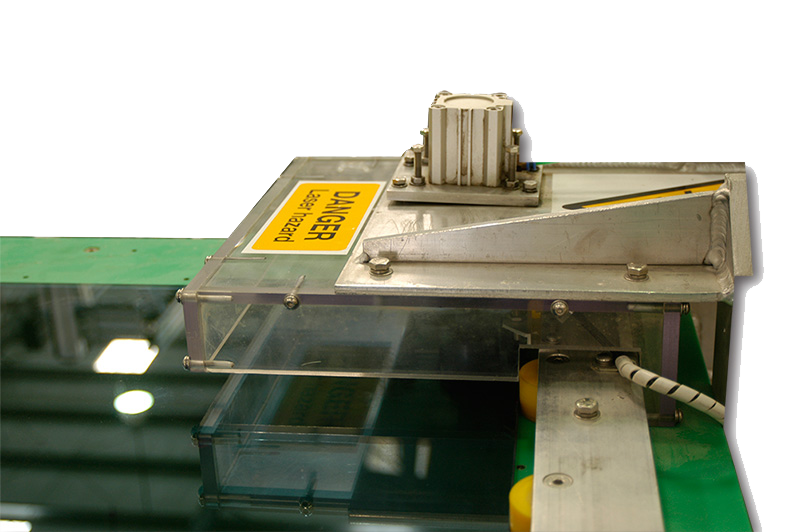

Focused on each glass pane

Our unique laser marking system identifies each pane of glass by embedding it with a humanly readable code. Our tracking network is programmed real-time and offers complete traceability to ensure enhanced quality control for your projects. Nothing leaves unnoticed!

Reduced handling,superior quality!

Seamless integration & higher efficiency

Cut glasses are transferred horizontally directly onto arising line eliminating unnecessary handling steps and maintaining quality of glass surfaces. Integrated setup allows better planning and reduces human errors.

Our customized special pre-wash system are capable of removing temporary protective overcoat of certain triple silver glasses through mechanical systems thus avoiding use of harmful chemicals/ detergents in water.

For that perfect hole, everytime!

Operable with bar-coding system and able to process glass doors with complete polishing and fabrication in as fast as 7 minutes per Glass door. CAD-CAM interface provides high fabrication accuracy and relieves you of hole-matching hassles at site.

The integrated system minimizes handling thus providing scratch-free, chip-free, mark-free high quality glass product.

Bring life to your facades!

Benefit from our varied experience with glass and colours

Our unique seamlessly integrated Ceramic printing line provides end-to-end processing from warehouse to printing. Superior design capabilities allow us to imprint your imagination on glass.

No offloading of glass before printing thus providing a stain-free end product of premium quality. We can print on the most sensitive glasses!.

Turbo engines to exceed today’s benchmarks

Turbo-charged top-bottom convection tempering machine from Uniglass (Glaston)

Finland capable of processing the most advanced glasses with emissivity as low as 0.01. Quicker furnace for the quality experts who want to settle for nothing but the best! Our furnace and systems allow us to achieve distortion parameters exceeding the global standards.

For the extra protection.

We are capable of performing Heat Soak test as per EN standards of tempered glass to ensure you get a product that may not fail

ENHANCED SAFETY with unmatched Quality

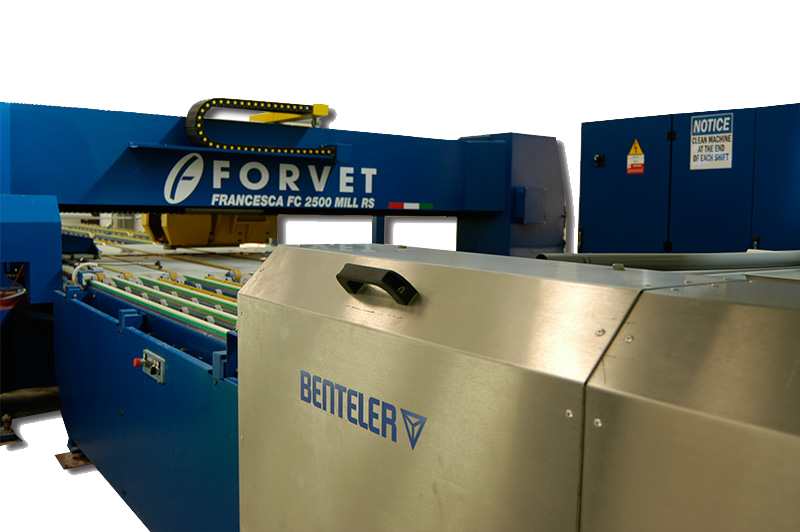

Heavy duty infrastructure for your complicated designs

Lamination line from Benteler, Germany is capable of processing laminated sheets as fast as 75 seconds per sheet. The automated line is equipped with precise assembly of glass panels and an automatic PVB cutting system for high speed processing.

The sturdy machinery can process Iaminated Glass panels with thickness upto 100mm for multi-layered and bullet resistant glasses.

Patented Robotic Sealant Application System for Insulated Glass.

Hand-work is best left for creating artistic masterpieces.

Fully automated insulating line from Lisec, Austria with automatic 4-sided step glazing and auto-sealing system. Specialized schuco spacer sealing equipment to enhance quality of insulated glass product and accelerate insulating line processing.

Dedicated quality laboratory for 100% product testing.

Because you deserve only the best.

A dedicated quality laboratory with the industry's most comprehensive range of test equipments firmly maintains material, production and product quality for that perfect product, every time.

Complete Production and Process Control through ERP system.

Data at your fingertips.

A sophisticated production software network integrated to the central ERP system monitors all administrative and factory operations and provides real-time data and live updates at every step of order process. Track your orders anytime, anyplace!